-

YIHOO FR950

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

YIHOO FR950

Product name Chloroalkyl polyphosphate ester CAS number 52186-00-2 Formula product form clear or light yellow liquid Specification Item Standard Color(Hazen) 200 max Gravity(20°C, g/cm3) 1.32-1.34 Acid Value(KOH mg/g) 0.30 max Water(%) 0.10 max Viscocity(25°C, mPa∙s) 700-1100 TCPP content(%) 3.00 max Application FR950 is a chlorophosphate flame retardant, especially suitable for polyurethane foaming. Compared with other flame retardants, its advantages lie in its high flame retardancy, low fog, low coke core, and low toxicity.

It is suitable to pass California 117 standard, automotive sponge FMVSS302 standard, British standard 5852 CRIB 5 flame retardant test standards. FR950 is an ideal flame retardant to replace TDCPP (carcinogenicity) and V-6 (containing carcinogenicity TCEP).Package 250kg drum -

YIHOO FR9220

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

YIHOO FR9220

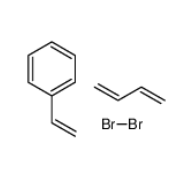

Chemical name 1,1’ Sulfonyl Bis[3,5-dibromo-4-(2,3-dibromopropoxy)]benzene CAS number 42757-55-1 Molecular structure Product form white powder Specifications TEST SPECIFICATION Bromine content content 64% MIN Melting Point 110℃MIN White(Hunter) 90MIN Loss on Drying , WT.% 0.3% MAX Application Mainly used as flame retardant. Pakcage 25kg carton -

YIHOO FR970

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

YIHOO FR970

Chemical name bromine SBS CAS number 1195978-93-8 Molecular structure Product form White powder Specifications TEST SPECIFICATION bromine content (%) 64.00 min Softening point (℃) 120.00 min Loss on drying (%) 0.30 max Application FR970 is a highly effective brominated polymeric flame retardant for polystyrene foams, It provides outstanding thermal stability and excellent flow properties and UV resistance with polymeric structure.

FR970 offering comparable flame retardant performance in polystyrene form to Hexabromocyclododecane with same bromine content. It is a perfect alternative to replace HBCD in EPS and XPS foams, requiring minimal reformulation in current production lines.Pakcage 20kg bag -

YIHOO MD12

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

YIHOO MD12

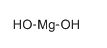

Chemical name Magnesium hydroxide (modified) CAS number 1309-42-8 Molecular structure Product form White powder Specifications TEST SPECIFICATION Mg(OH)2 (%) 80.00 min CaO (%) 3.50 max Acid insoluble matter (%) 15.00 max Fe3+ (%) 0.30 max Moisture (%) 0.5 max Particle size (D50) (um) D50≤5 Whiteness (%) 80.00 min Stearic acid (%) 2.00max Application Magnesium hydroxide is an excellent flame retardant for plastics and rubber products. In terms of environmental protection, it can replace caustic soda and lime as a neutralizing agent for acid-containing wastewater and an adsorbent for heavy metals. In addition, it can also be used in the electronics industry, medicine, sugar refining, as insulation materials and the manufacture of other magnesium salt products. Pakcage 20 kg/bag -

YIHOO AN1520

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

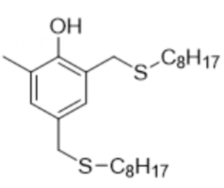

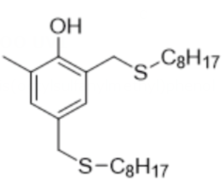

YIHOO AN1520

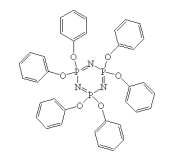

-

YIHOO ZINC BORATE

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

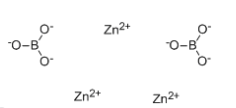

YIHOO ZINC BORATE

Chemical name ZINC BORATE CAS number 10361-94-1 Molecular structure Product form White powder Specifications TEST SPECIFICATION Whiteness,> 95 Particle size (D50,um) 3-5 Zno,% 37-40 B2O3,% 45-48 Surface water,%,105C 0.5 Loss of igniteon,450°C 12.5-14.5 Pb,PPM,< 10 cd,PPM,< 5 Fe,PPM,< 30 Application Zinc borate (ZB for short) is a multifunctional additive with flame retardant, charcoal-forming, smoke suppression, smoke suppression and melt dripping effects. Pakcage 25kg carton -

YIHOO FR960

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

YIHOO FR960

Product description FR930 is a phosphorus-based environmentally friendly halogen-free flame retardant, full name diethylphosphinate. This flame retardant is a white powder, organic phosphinate. The product is moisture-proof, insoluble in water and acetone, dichloromethane, butanone, toluene and other organic solvents.

It is especially suitable for halogen-free flame retardant of high-temperature nylon engineering plastics (6T, 66&PPA, etc.), polyurethane elastomer (TPU), polyester elastomer (TPE-E) and other systems.CAS number 1184-10-7 Molecular structure Product form white powder Specifications TEST SPECIFICATION Phosphorus content(%) 23.00-24.00 Water(%) 0.35 max Density(g/cm³) Approximate 1.35 Bulk density(kg/m³) Approximate 400-600 decomposition temperature(℃) 350.00 min Particle size (D50)(μm) 20.00-40.00 Advantages ●Excellent water resistance, no hydrolysis, no precipitation;

●Suitable for thermoplastic and thermosetting plastics;

●High phosphorus content, high flame retardant efficiency;

●UL94 V-0 rating can achieve 0.4 mm thickness;

●Good thermal stability, processing temperature can reach 350 ℃;

●It is applicable to both glass fiber reinforced and non glass fiber reinforced;

●Flame retardant materials have good physical and electrical properties;

●Suitable for lead-free welding;

●Good coloring performance;

●Halogen free flame retardant is beneficial to environmental protection and health.Application FR930 is a flame retardant suitable for thermoplastics and thermosets. It has high phosphorus content, good thermal stability and high flame retardant efficiency.

Due to the good high temperature stability of FR930, it can be applied to high temperature nylon, suitable for glass fiber reinforced and non-reinforced type. The flame retardant material has good physical and electrical properties.

In high-temperature nylon, FR930 is used in an amount of approximately 10% (wt) to achieve UL 94 V-0 (1.6 and 0.8 mm thickness). The amount of flame retardant used may vary depending on the polymer, processing conditions, and amount of glass fiber added.Processing technology Before adding FR930, it is necessary to pre-dry the polymer as usual. If possible, the moisture content of high-temperature nylon should be less than 0.1% by weight, PBT should be less than 0.05% by weight, and PET should be less than 0.005%. Pre-drying of ADP-33 is not required. However, if the system has low moisture content requirements, pre-drying is recommended (e.g. baking at 120°C for 4 h);

The commonly used mixing and processing method of powder can be used for FR930, and the best dosing method should be determined on a case-by-case basis. It must be ensured that all components are evenly dispersed and that the temperature of the polymer melt does not exceed 350°C.Pakcage 25kg bag -

YIHOO FR930

QINGDAO YIHOO POLYMER TECHNOLOGY CO. LTD.

TECHNICAL DATA SHEET

YIHOO FR930

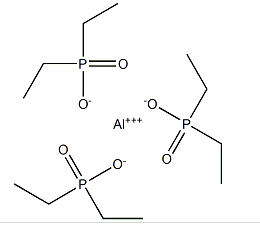

Product description Yihoo FR930 is a halogen-free flame retardant based on organic phosphinates,white powder,called Aluminum Diethyl Phosphinate.The product is not hygroscopic and is insoluble in water and common organic solvents like acetone, dichloromethane, MEK, toluene and so on.

It’s mostly suitable for 6T、66&PPA, TPU and TPE-E.CAS number 225789-38-8 Molecular structure Product form white powder Specifications TEST SPECIFICATION Phosphorus(%) 23.00-24.00 Water(%) 0.35max Density(g/cm³) app. 1.35 Bulk Density(kg/m³) app. 400-600 Decomposition Temperature(℃) 350.00min Average Particle Size (D50)(μm) 20.00-40.00 Addvantage Non-hygroscopic, not hydrolyzed and not precipitated

Suited as flame retardant for thermoplastics and thermosets

High efficiency due to its high phosphorus content

UL 94 V-0 rating down to 0.4 mm thickness

Suited for processing temperatures up to 350 °C

Suitable for both glass fiber reinforced and unreinforced grades

The flame retardant polyamide compounds exhibit very good physical and excellent electrical properties

Suitable for lead free soldering

Good colorability Non-halogenated flame retardant with favorable environmental and health profileApplication FR930 is suited as flame retardant for thermoplastics and thermosets. Due to its high phosphorus content the product is distinguished by a high efficiency. FR930 can even be applied in high temperature polyamides because of its high temperature stability. It is suitable for both glass fibre reinforced and unreinforced grades. The flame retardant polyamide compounds exhibit very good physical and electrical properties.

In high temperature polyamides of PA 6T/66 type, a dosage of approx. 15 % (by wt.) FR930 is usually sufficient to obtain the UL 94 V-0 classification for electrical compounds (at 1.6 as well as 0.8 mm thicknesses). Subject to the polymer grade, processing conditions and glass fibre reinforcement the dosage of the flame retardant may vary.Processing Before incorporating FR930, it is important to predry the polymer as usual. If possible, the resulting moisture content should be below 0.1 % (by wt.) for high temperature polyamides, 0.05 % (by wt.) for PBT and 0.005% for PET. Predrying of FR930 is not necessary. However, predrying (e. g. 4h at 120 °C) is recommended, if even very low moisture contents must be avoided. The mixing and processing methods customary in powder processing of polymers can be used with FR930. The optimum conditions for incorporating should be determined in each individual case. Care must be taken to ensure homogeneous dispersion of all components. The temperature of the polymer melt should not exceed 350 °C. Pakcage 25kg bag -

REY-16 tombarthite Y molecular sieve

containing RE2O3 mixed tombarthite oxide ≥16.5%, according to user needs, can adjust the proportion of La2O3 and CeO2 in rare earth.

-

RUSY-12 tombarthite Y molecular sieve

containing RE2O3 mixed tombarthite oxide ≥12%, according to user needs, can adjust the proportion of La2O3 and CeO2 in rare earth.

-

RUSY-8 tombarthite superstable Y molecular sieve

containing RE2O3 mixed tombarthite oxide ≥7%, according to user needs, can adjust the proportion of La2O3 and CeO2 in rare earth, the size of the cell parameters can be adjusted according to user needs.

-

DAY-12 low Na, superstable, high Si molecular sieve

Na2O≤0.1%, SiO2/Al2O3 molar ratio ≥10.