Although nylon has excellent mechanical and mechanical properties, it is highly combustible in terms of chemical combustion properties, and also has the phenomenon of melting drops during combustion, which has a great degree of safety potential hazards. The vertical combustion properties of pure nylon were measured with the V-0 grade of UL-94, LOI value greater than 24%. Therefore, the new flame retardant technology of nylon has become a hot topic which has aroused the common concern of many scientists all over the world.

FIG.1

Figure source: Youbian stock official website

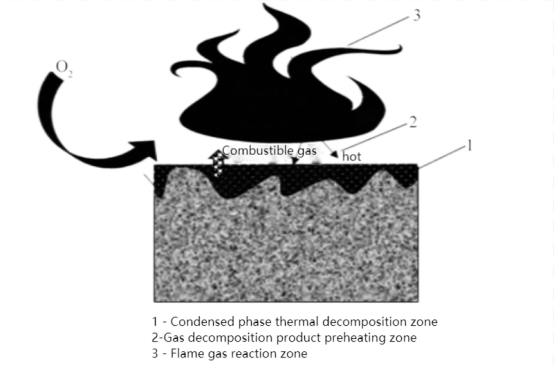

In recent years, with the global environmental protection , green development and non-carbon halogenation voice is more and more high, green environmental protection flame retardant has been praised and recognized by everyone. Green environmental protection flame retardant with flame retardant high efficiency, non-halogenated, non-toxic, low smoke and environmental protection is now a major direction in the development of the new flame retardant industry in China. Figure 2 is a schematic diagram of the polymer combustion process.

FIG. 2 Schematic diagram of polymer combustion process

FIG. 3 Polypetrochemical halogen-free flame retardant PA66, PA6 connectors, fasteners

FIG. 4 Flame retardant nylon for Sanyang electric vehicles

Ⅰ. types of flame retardants

Flame retardant additives are flame retardants which can prevent combustion decomposition of combustion materials and inhibit upward propagation of combustion flame.

Up to the current market situation in China, the products of added flame retardant additives are still the main products which constitute the current flame retardant market structure on the whole and there are always contradictions in the market structure in China. Although the technology of added flame retardant polymer materials is simple compared with traditional methods, it can basically meet the requirements of traditional flame retardant materials process. Therefore, the number of new types of flame retardants produced and manufactured is more.

However, it is easy to cause or affect the physical and mechanical properties and processing characteristics of the material as a whole as well as various special applications and safety properties, and often there are a variety of serious problems such as uneven distribution of dispersion degree, serious matrix compatibility defects and interface force is not very close to the ideal value.

The characteristics of reactive flame retardants are that they can quickly obtain a relatively low temperature, relatively durable and good stable reaction and flame retardant effect in the above-mentioned polymer material mixtures. Moreover, the toxicity degree of the reactive materials is relatively low, and the effect of the reaction interface force in the reactive polymer material mixtures is also small, but the production process is more complicated and not easy to operate.

According to the different types of elements in the main flame retardant substances, flame retardants can be further divided into bromine element series, chlorine element series, organophosphorus series, organosilicon calcium series, magnesium series and metal aluminum series. According to the classification and standard of whether the substance is reduced to active organic matter, the general substance can be divided into general organic flame retardant and ordinary inorganic flame retardant.

FIG.5

Figure source: Official website of the Emperor

In the past two years, the pursuit of more safe and efficient, non-toxic, low black smoke, pollution-free production and efficient clean, dust-free operation of new flame retardant products has gradually begun to develop into a domestic organic and flame retardant environmental chemicals field technology and development research breakthrough one of the most important trends.

Ⅱ.the application of flame retardant in polyamide

1. Inorganic flame retardant

Inorganic flame retardant mainly refers to as a semi-natural and environmental protection compound additives, the use of objects will be very wide. At present, Mg(OH)2, Al(OH)3 and other hydroxides are still a new type of natural inorganic compound flame retardants which are the main industrial applications in China.

Taking Mg(OH)2 as a typical example, it has the functions of enhancement, flame retardancy and smoke suppression. The main physical and flame retardant oxidation reaction mechanisms are roughly as follows: the endothermic cosycophous reaction of strong thermal oxidation can realize the transient cross-linking effect on the intermediate transition from slow cooling to fast cooling of high temperature polymer materials.

At the same time, due to the large amount of low saturated high temperature water vapor released after the occurrence of crosslinking reaction, it can also achieve temporary oxidation and concentration of part of combustible and harmful gases, and inhibit the combustion decomposition and extension of some products in high temperature combustion. At the same time, the high-temperature refractory organic metal oxides decomposed by oxidation also have higher flame-retardant oxidation activity of flame-retardant materials, which itself will undergo rapid chemical changes in a moment and produce strong thermal oxygen dissociation and crosslinking in high temperature polymer solution.

The surface of these high temperature polymer materials can be rapidly oxidized to form a thick layer of non-carbonized film, carbonized film surface will quickly and significantly weaken the heat transfer effect of heat convection and heat mass transfer effect caused by high temperature in flame and combustion, so as to finally play the role of heat preservation, flame retardant and adiabatic.

FIG.6 Inorganic flame retardant

The inorganic type of inorganic flame retardant added to polymer materials is not very much at present, and because most of the current organic polymer flame retardant materials are first added to the polyamide composite material system by a chemical physical polymerization process, under the condition of physical dispersion polymerization and the organic polymer between not very full mixing, Therefore, it seems that this polymer compound flame retardant has not been further developed and applied more widely and effectively.

The common types of several new inorganic flame retardant materials are roughly phosphoric acid, boric acid, sodium phosphate p-ammonium chloride, sodium borax and so on. Jin Xuefen et al. proposed that two products such as nylon and nylon 66 were added with hypophosphate to enhance the flame retardant. The study focused on the three components of ferric oxide (Fe2O3) and a series of comprehensive factors influencing the improvement of flame retardant and decomposition properties of the flame-retardant system materials and their effects.

Through the analysis of cone calorimeter data, the analysis of pyrolysis weight loss data and the comparative analysis of topography, it is found that Fe2O3 has a relatively obvious, effective and lasting flame retardant effect on the flame retardancy of hypophosphate and enhanced PA66 system, promoting reaction and decomposition. The effective and lasting combustion blocking of the solid porous carbonized layer limits the rapid release velocity peak of the energy of combustible or harmful gas molecules, and the rapid energy transfer between harmful gas heat molecules significantly reduces the rapid heat release rate of combustible or harmful gas heat molecules in the barrier system.

FIG.7 Nylon flame retardant

Figure source: Official website of Yinyuan New Materials

With Exolit OP 1312 Ml flame retardant GRPA66(glass fiber content of 30%), when the amount of flame retardant is 18%, the flame retardant of UL94V-0, open combustion D4min flame retardant is 50% lower than BPS and RP, the material density and CTI value are the same as the non-flame retardant substrate, melt index is 30% lower than the substrate, but much higher than with BPS and RP flame retardant.The tensile and impact strength is reduced by about 20% compared with non-flame retardant GRPA66, and the flame retardant material color and transparency are better. Compared with BPS and RP flame retardant GRPA66, such as comprehensive consideration of processing, flame retardant, smoke, mechanical and electrical properties, flame retardant GRPA66 with Exolit OP 1312 M1 has obvious advantages.

With the gradual increase of the proportion of halogen-free flame retardant additives, the flame retardant strength of UL94 grade of reinforced materials such as nylon 66 will be significantly increased, and the residual flame time will be significantly shorter. When the total addition ratio of halogen-free flame retardant is only about 20% on average, In the halogen-free flame retardant reinforced material system, the flame retardant performance of UL94 of nylon 66 can reach the level of UL94V-0, and the average notched impact strength of simply supported beams in mechanical properties is about 7.5kJ/m²

Levchik et al. ‘s work revealed that red phosphorus and a variety of other flame retardant additives in nylon 6 have mutually promoting flame retardant effect and flame retardant properties.

LvchickSV added 3 parts of red phosphorus and 1 part of Mg(OH)2 and other flame retardant additives into nylon, respectively. The total content of the two ingredients accounted for 20%~50% of the total volume of resin material. It can ensure that the comprehensive technical indicators of the production and the quality of the products can be better, and the grade of the flame retardant property of the material can meet the requirements of the international standard UL94V-0 level and the requirements of the CTI value of the Chinese standard does not exceed or less than the polymer generated by the 400V current of the power supply.

2. Organic flame retardant

2.1 Phosphorous flame retardants

In phosphate ester flame retardant materials, it is generally divided into elemental materials containing halogen-free phosphate ester elements and composite materials containing halogen-free phosphate ester components according to whether it will be alone or contain a small amount of inorganic halogen compounds.

FIG.8 Phosphorous flame retardants

Figure source: Tianyi Chemical website

Non-halogen phosphate ester products do not need to contain a small amount of other halogen elements alone,and do not exist in other volatile organic metal halogen compounds flammable in the combustion environment with any pollution and risk factors.It has become a new technology direction in the rapid development of science and technology in the field of fireproof coatings at home and abroad.

Triphenyl polyphosphate, isotriazole toluene sulfonate phosphate, triallyl phosphate and other non-halogen-type polyphosphate derivatives have more than a dozen of their main raw materials. However, because they contain many components, halogen-free polyphosphate products also have many quality defects, such as high solvent volatility, low heat and low temperature performance and poor molecular compatibility performance. Therefore, its extensive production and application in non-halogenated polymer phosphate ester products are severely limited.

Triisopropyl phosphate, which was successfully developed by a large Swiss federal company in 1968, has the main characteristics of ultra-low toxicity, low viscosity, odorless, in line with the requirements of light resistance, green environmental protection, ultraviolet resistance, low temperature resistance and stress cracking resistance. The preparation and production process of triisopropylbenzene phosphate is simple, the raw material channels and sources are wide, it is widely used in organic polymer, inorganic polymer, natural polymer and other fields of material products flame retardant.

Yang Minfen et al. showed that the ultimate oxygen content index increased with the increase of the ratio of flame retardants. When the addition amount of bis (2-carboxyethyl) monohexamethylamine phosphate was 6%(mass fraction), the LOI value could reach 27.8%UL-94 level. Tests showed that when the addition ratio of bis (2-carboxyethyl) monohexamethylamine phosphate was higher than 2%(mass fraction), the melt drop phenomenon of flame retardant nylon 66 was significantly improved to pass the V-0 grade of UL-94.

Wang Zhangyu et al. added themselves to the 66 polymerization of nylon monomer and could first synthesize or screen out the excess melamine polyphosphate monomer (MPP) for polymerization. The test results all showed that when the total amount of MPP in the monomer reached 25%(mass fraction) or above, The highest value of flame retardant and protective properties can be directly or reached the international UL94 grade V-0, but the maximum tensile yield ultimate strength of the polyamide composite can be 120MPa, impact toughness strength can be 6.7kJ/m².

Phosphorus type flame retardants have the unique advantages of non-toxic, low halogen, low smoke, environmental protection and no heavy metal pollution substances, and they are the most indispensable among many organic polymer flame retardants, which will gradually become a new direction of human research.

2.2 Nitrogen type flame retardant

At present, nitrogen flame retardants can be widely used and applied to engineering applications in China. Among the main types of nitrogen flame retardants, melamine resins and their corresponding derivatives are the main ones. One of their remarkable characteristics is that their flame retardancy, decomposition and combustion efficiency coefficient is high, completely harmless, non-toxic and cheap.

FIG.9

Figure source: Koon flame retardant materials official website

The main oxidation mechanism of nitrogen-type flame retardants involves two to three main gas phase mechanisms: valence oxynitrous compounds usually decompose and oxidize gradually in the combustion exchange of high temperature flame and react to form NH3 and free N2, and release a large number of non-flammable gases containing nitrogen atoms such as NO and water vapor, which can greatly reduce the oxygen concentration while absorbing heat to cool down. Nitrogenous flame retardants are a new type of flame retardants with low toxicity, relatively poor volatility and high stability.

The main varieties of nitrogen flame retardants are triazine cycloketone compounds, melamine derivatives, etc. Gijsma et al. also studied that MCA added to polyamide has a significant impact on the performance of polyamide. The research report showed that: The reasonable addition of MCA into nylon can not only effectively solve the problem of drip fire caused by nylon fuel in normal combustion work, but also play a good role in its own flame retardant performance, combustion grade can reach UL94V-0, LOI value can be greater than 31.0%.

Wang Qi et al. added a new type of high dispersion MCA polymer (FS-MCA) prepared by proprietary technology to the flame-retardant nylon plastic PA66 for PA66 flame-retardant, using the excellent characteristics of small bonding reaction between particle layers of poly FS-MCA, uniform, fluffy and stable particle structure after aggregation. The high efficiency and uniform fine dispersion of flame retardant molecules in polymer PA66 resin can be achieved, which effectively improves the flame retardant and mechanical properties of MCA flame retardant PA66 system.

DianLuo successfully prepared modified MCA with low surface energy and flow energy by surface treatment of low molecular weight nylon.

FIG.10 MCA flame-retardant nylon masterbatch

Figure source: Polypetrochemical

Compared with traditional MCA, modified MCA has special surface properties and is easier to flow and disperse in PA66 resin. The modified MCA flame retardant added into PA66 matrix has higher fluidity, better flame retardancy and enhanced mechanical properties. Therefore, the improved MCA can overcome the disadvantages of traditional MCA. It provides a promising technology, by using this modified MCA can be prepared excellent comprehensive performance of flame retardant enhanced PA66.

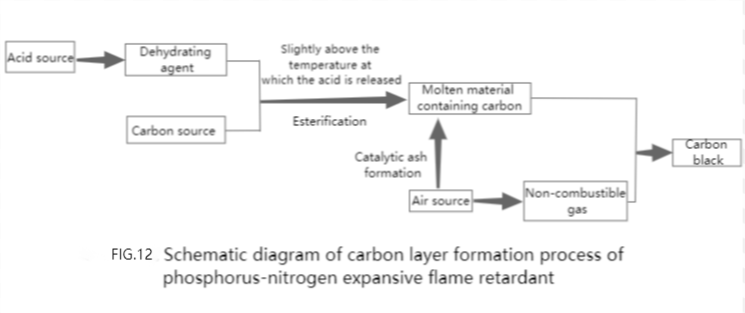

2.3 Phosphorus-nitrogen expansion flame retardant

The principle of expansive flame retardant mainly refers to the use of these three completely different physical and chemical properties of material flame retardant elements in the block of material gas continued combustion process changes can also be added by their separate components to the flame retardant material combustion effect, so as to achieve a real stop of combustible material gas continued expansion and combustion. The main components are also completed by carbon source, acid source and air source.

FIG.11 Expansive flame retardant

Figure source: Hongtaiji official website

Carbon sources, as the name implies, burn most of the carbon contained in a material’s molecular structure. Carbon-containing materials generally belong to combustible materials. However, due to the chemical properties of carbon itself, after decomposition in high-temperature gas combustion and other processes, it usually gradually dissolves to form another carbon layer, which acts as a carbon melt drop formed in the remaining gas combustion materials after the decomposition of oxygen into combustion and other processes.

As the name suggests, acid source refers to most of our daily processed polyphosphate. Some high-temperature gas flame retardants containing polyphosphate compounds can precipitate the formed gas polyphosphate gas in the process of high-temperature combustion reaction to fill the material surface relying on the combustible polymer material skeleton to effectively block the flame of the flame retardant material to continue to burn at low temperature.

As the name implies, air source refers to the gas groups contained in the molecular structure skeleton of materials during low-temperature combustion, which can block an inert gas released in the process of low-temperature combustion, so as to further dilute the harmful air remaining on the surface of materials burned at high temperature, so as to further achieve the double flame retardant protection effect of flame retardant and heat insulation.

Zhang Xujie et al. developed a kind of environmental protection, green and efficient phosphorus and nitrogen series flame retardant additives can be used for the late flame retardant of flame retardant nylon. The combustion temperature of the late flame retardant nylon products produced by preparation can reach the EU UL94V-0 level, which solves the common problem of melting drops in the late combustion process of nylon products. However, due to the existence of a large number of aromatic hydrocarbons in this highly efficient flame retardant structural material, it will cause extremely high explosive rupture in the late flame retardant textile system of nylon products due to the special reason of a large amount of benzene ring content. Therefore, there are still many problems in the formulation design of flame retardant of nitrogen and phosphorus compounds in our country, which needs to be further improved.

The initial heating and decomposition reaction temperature range of phosphorus – nitrogen expansion flame retardant is generally about 200℃. The weight loss reached 5% at about 240℃, and the rate range of pyrolysis reaction at about 378℃ was also the largest in the world at that time. The final result was that when the decomposition temperature range was about 600℃, the thermal decomposition of flame retardants could be completed simultaneously, and the mass retention rate could reach about 36.5%.

Li Xia et al. first synthesized and measured two carboxyl groups in the structure of a nitrogen-phosphorus type flame retardant. After people used it, it would further react with cyclophosphine and decompose into a flame retardant salt, and finally synthesized a nylon 66 flame retardant compound.

The experimental test also showed that its LOI was more than 27.14%, and the test result obtained by vertical combustion test was UL94V-0. And in the vertical combustion process will also see on the surface of the material gradually formed a soft dense and uniform thickness of carbonized layer, to solve the vertical combustion process of dripping phenomenon. The carbon layer formed by phosphorus – nitrogen expansion flame retardant is shown in the figure below.

Ⅲ.Conclusion and Prospect

The appearance of halogen-free flame retardant makes flame-retardant polyamide products in normal combustion operation will not produce any substances that produce harmful reactions to the human body and the environment again. The series of halogen-free flame retardant products of polyamide has gradually become a popular product on the market. Halogen-free flame retardants red phosphorus and cyanuric acid are two kinds of polyamide products with relatively good market application and development prospects.

FIG.13 Flame-retardant polyamide material

Figure source: Defu Plastic Net

Red phosphorus has high flame retardant and decomposition efficiency, so it can effectively improve the inherent heat resistance and arc resistance of flame retardant and product material itself, but at present, in view of its storage and transportation mode of storage and transportation and some technical limitations in the color of the product has been greatly restricted and affected the current color problems of its products in nylon common application, It is generally used only in nylon 6.

FIG.14

Another new halogen-free flame retardant mainly used in polyamide is melamine urate. The main active components may be melamine salt derivatives and phosphate derivatives. Although they have good flame retardant properties, they have poor thermal stability. Because of its easy oxidation and moisture absorption, the electrical corrosion performance of these products is relatively poor under the action of high temperature and humid environment for a long time.

FIG.15 Melamine cyanuric acid

Figure Source: Xiucheng Chemical official website

Although several other common halogen-free inorganic flame retardant materials used in this paper have their own particularity and advantages, they all have a series of problems, such as very low self-flame retardant efficiency, poor binding force with the material interface, large addition amount and great performance reduction. Therefore, the flame retardant effect of single inorganic or organic flame retardant additives is often not ideal.

Therefore, more scholars tend to use the combination method of 2 or even more than 2 kinds of flame retardants to compound flame retardants with different properties, and make use of their own advantages to produce a variety of synergistic promoting effects, so as to obtain a higher grade of comprehensive flame retardant performance. At present, the efficiency of nitrogen-phosphorus compound flame retardant is higher, the market production reserve is more, and the product is green and pollution-free.

Therefore, nitrogen and phosphorus flame retardants are also one of the most important future development directions in the field of flame retardation of polymer materials in China. At present, a large number of new flame retardants have emerged in the market.

We supply all kinds of halogen-free, phosphorous and bromine flame retardants, which are widely used by customers in Europe and the United States.

Enquiries are welcome at any time: yihoo@yihoopolymer.com

Post time: Feb-27-2023