Ⅰ.Nylon 6 injection molding process

1.Chemical and physical properties

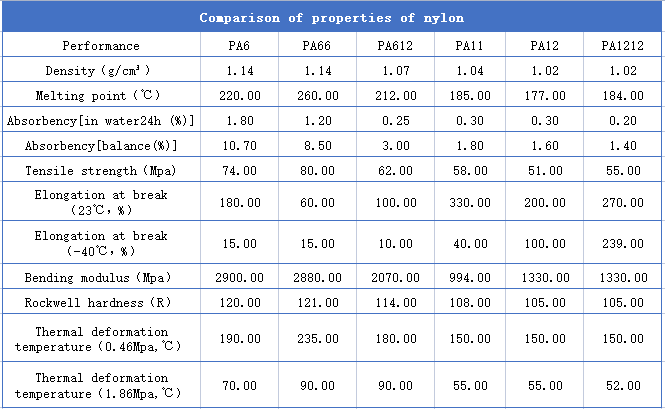

The chemical and physical properties of PA6 are similar to those of PA66; however, it has a lower melting point and a wide process temperature range.Its resistance to impact and solubility is better than that of PA66, but it is also more hygroscopic. Since many quality characteristics of plastic parts are affected by hygroscopicity, this should be fully taken into account when designing products using PA6.

In order to improve the mechanical properties of PA6, a variety of modifiers are often added. Glass is the most common additive, and sometimes synthetic rubber, such as EPDM and SBR, is added to improve impact resistance.

For products without additives, PA6 shrinkage is between 1% and 1.5%. The addition of fiberglass additives reduces the shrinkage rate to 0.3% (but slightly higher perpendicular to the process). The shrinkage rate of molding assembly is mainly affected by crystallinity and hygroscopicity of materials. The actual shrinkage rate is also a function of the plastic design, wall thickness and other process parameters.

2.Process conditions of injection mold

(1) Drying treatment:Since PA6 absorbs water easily, special attention should be paid to drying before processing. If the material is supplied in a waterproof packaging, the container should be kept airtight. If the humidity is greater than 0.2%, it is recommended to dry in hot air above 80 ° C for 16 hours. If the material has been exposed to air for more than 8 hours, it is recommended to vacuum dry it in hot air at 105℃ for more than 8 hours.

(2)Melting temperature :230~280℃, 250~280℃ for reinforced varieties.

(3)Mold temperature: 80~90℃. Mold temperature significantly affects the crystallinity, which in turn affects the mechanical properties of plastic parts. Crystallinity is very important for structural parts, so the recommended mold temperature is 80~90℃.

For thin-walled plastic parts with a long process, it is also recommended to apply a higher mold temperature. Increasing the mold temperature can improve the strength and stiffness of plastic parts, but reduce the toughness. If the wall thickness is greater than 3mm, it is recommended to use a low-temperature mold of 20 to 40℃. For glass fiber reinforced material mold temperature should be greater than 80℃.

(4)Injection pressure: Generally 750 to 1250bar (depending on material and product design).

(5)Injection speed: High speed (slightly lower for enhanced materials).

(6)Runner and gate: The location of gate is very important due to the short solidification time of PA6. Gate aperture should not be less than 0.5*t (where t is the thickness of plastic parts).

If a hot runner is used, the gate size should be smaller than if a conventional runner is used, as the hot runner can help prevent premature solidification of the material. If a submerged gate is used, the minimum diameter of the gate shall be 0.75mm.

PA6 injection molded products

Ⅱ.Nylon 66 injection molding process

1.Drying of nylon 66

(1)Vacuum drying: Temperature 95-105 for 6-8 hours

(2)Hot air drying: temperature 90-100 ℃ for about 4 hours

(3)Crystallinity:In addition to transparent nylon, nylon is mostly crystalline polymer, high crystallinity, tensile strength, wear resistance, hardness, lubrication and other properties have been improved, thermal expansion coefficient and water absorption tend to decline, but on the transparency and impact resistance. Mold temperature has great influence on crystallization, high mold temperature high crystallinity, low mold temperature low crystallinity.

(4)Shrinkage rate: similar to other crystalline plastics, nylon resin shrinkage rate is larger problem, general nylon shrinkage and crystallization relationship is the largest, when the product crystallinity is large product shrinkage will increase, in the molding process to reduce the mold temperature or increase the injection pressure or reduce the material temperature will reduce shrinkage, but the product internal stress increase easy deformation. The shrinkage rate of PA66 is 1.5-2%.

(5)Molding equipment: nylon molding, the main attention to prevent the “nozzle flow phenomenon”, so the processing of nylon material generally choose self-locking nozzle.

2.Products and molds

(1) Wall thickness of products:The length ratio of nylon is between 150-200, the wall thickness of nylon products is not less than 0.8mm, generally between 1-3.2mm, and the shrinkage of products and products related to the wall thickness, the thicker the wall thickness, the greater the shrinkage.

(2) exhaust gas:The overflow edge value of nylon resin is about 0.03mm, so the vent groove should be controlled below 0.025.

(3) mold temperature:Products with thin walls are difficult to form or require high crystallinity of the mold heating control, the product has a certain flexibility of the general use of cold water temperature control.

Nylon 66 injection molded products

3.Forming process of nylon 66

(1)Barrel temperature: Because nylon is a crystalline polymer, so the melting point is obvious, nylon resin in the injection molding of the selected barrel temperature is related to the performance of the resin itself, equipment, product shape factors. Nylon 66 is 260℃. Due to the poor thermal stability of nylon, it is not suitable to stay in the cylinder at high temperature for a long time, so as not to cause material discoloration and yellowing, at the same time because of the good fluidity of nylon, the temperature exceeds its melting point after the rapid flow.

(2)Injection pressure: nylon melt has low viscosity and good fluidity, but the condensation speed is fast. It is easy to have insufficient problems on products with complex shape and thin wall thickness, so it still needs higher injection pressure. Usually the pressure is too high, products will overflow problems; If the pressure is too low, the products will produce ripples, bubbles, obvious fusion marks or insufficient products and other defects. The injection pressure of most nylon varieties is not more than 120MPA, and the selection is generally within the range of 60-100MPA to meet the requirements of most products. As long as the products do not appear bubbles, dents and other defects, it is generally not expected to use higher pressure retention. So as not to increase the internal stress of the product.

(3)Injection speed: For nylon, the injection speed is fast, which can prevent the ripple caused by too fast cooling speed and insufficient filling problems. Fast injection speed has no significant effect on the properties of the product.

(4)Mold temperature: mold temperature has certain influence on crystallinity and molding shrinkage. High mold temperature has high crystallinity, wear resistance, hardness, elastic modulus increase, water absorption decrease, and molding shrinkage of products increase; Low mold temperature, low crystallinity, good toughness, high elongation.

4.Nylon 66 forming process parameters

The rear temperature of the barrel is 240-285℃, the middle temperature is 260-300℃, and the front temperature is 260-300℃. The nozzle temperature is 260-280℃, and the mold temperature is 20-90 ℃. Injection pressure is 60-200MPA

The use of release agent: The use of a small amount of release agent sometimes has the effect of improving and eliminating bubbles and other defects. The release agent of nylon products can choose zinc stearate and white oil, etc., can also be mixed into paste use, use must be small and uniform, so as not to cause surface defects of products. In the shutdown to empty the screw, to prevent the next production, broken screw.

Ⅲ.PA12 injection molding process

1.PA12 injection molding process conditions

(1)Drying treatment:The humidity should be ensured below 0.1% before processing. If the material is exposed to air storage, it is recommended to dry in 85℃ hot air for 4 to 5 hours. If the material is stored in an airtight container, it can be used directly after 3 hours of temperature equilibrium.

(2)Melting temperature:240~300℃; Do not exceed 310℃ for materials with ordinary characteristics, and do not exceed 270℃ for materials with flame retardant characteristics.

(3)Mold temperature:30~40℃ for unenhanced materials, 80~90℃ for thin-walled or large-area components, 90~100℃ for enhanced materials. Increasing temperature will increase the crystallinity of the material. It is important for PA12 to accurately control the mold temperature.

(4)Injection pressure: up to 1000bar (low holding pressure and high melting temperature are recommended).

(5)Injection speed:High speed (preferably for materials with glass additives).

(6)Runner and gate:For materials without additives, the diameter of runner should be about 30mm due to the low viscosity of the material. For the enhanced material requirements of 5~8mm large runner diameter. The runner shape shall all be circular. The injection port should be as short as possible. A variety of gate forms can be used. Large plastic parts do not use small gate, this is to avoid excessive pressure on plastic parts or excessive shrinkage rate. Gate thickness should be equal to the thickness of plastic parts. If a submerged gate is used, a minimum diameter of 0.8mm is recommended. Hot runner molds are effective, but require precise temperature control to prevent material from leaking or solidifying at the nozzle. If hot runner is used, gate size should be smaller than cold runner.

Ⅳ.PA1010 injection process conditions

Because nylon 1010 molecular structure contains hydrophilic amide groups, easy to absorb moisture, its equilibrium water absorption rate is 0.8%~1.0%. Moisture has significant effect on the physical and mechanical properties of nylon 1010. Therefore, the raw material must be dried before use to reduce its water content to less than 0.1%. When drying nylon 1010 should prevent oxidation discoloration, because the amide group is sensitive to oxygen oxidation degradation. It is best to use vacuum drying when drying, because this method has high dehydration rate, short drying time and good quality of dried granules. The drying conditions are generally more than 94.6 kPa vacuum degree, 90~100 ℃ temperature, drying time 8~12h; The water content decreased to 0.1%~0.3%. If the use of ordinary oven dry operation, the drying temperature should be controlled at 95~105℃, and extend the drying time, generally need 20~24h. Dry materials should be carefully preserved to avoid moisture absorption.

1.PA1010 injection process conditions

(1) Plasticizing process

Before entering the mold cavity of nylon 1010 should reach the specified molding temperature, and can provide sufficient amount of molten material within the specified time, molten material temperature should be uniform. In order to meet the above requirements, screw injection molding machine is used according to the characteristics of nylon 1010, screw is mutation type or combined type. The barrel temperature increases successively from the hopper feed point forward. Because the barrel temperature control near the melting point is conducive to the improvement of the impact strength of products, and can avoid the leakage of materials, prevent material decomposition, the barrel temperature is generally 210~230 ℃. In order to reduce the friction between the screw and PA1010 during premolding, liquid paraffin wax can be used as lubricant, the amount is generally 0.5~2 mL/kg, and the mold temperature is generally 40~80℃. The increase of back pressure is conducive to compacting the material in the screw groove, removing the low molecular gas in the material and improving the plasticizing quality, but the increase of back pressure will increase the leakage flow and countercurrent between the screw and the barrel, so that the plasticizing ability of the injection molding machine is reduced. Plasticizing back pressure should not be too high, otherwise it will greatly reduce the efficiency of plasticizing, and even produce too much shear force and shear heat, so that the material decomposition. Therefore, under the condition of meeting the requirements of injection molding, the lower the plasticizing back pressure is, the better, generally 0.5-1.0mpa.

(2) Mold filling process:

In this process, attention should be paid to the injection pressure and injection speed of nylon 1010 injection molding. Generally, the injection pressure should be 2~5MPa, and the injection speed should be slow. If the injection pressure is too high and the injection speed is too fast, then it is easy to form turbulent flow, which is not conducive to eliminating the bubbles in the product. According to the changing characteristics of the pressure of the mold cavity, the process of injection molding can be divided into the stages of feeding the mold, flow filling and cooling. The cooling shaping process can be divided into three stages: pressure retaining and feeding, backflow and cooling after gate freezing.

Certain conditions must be met to realize pressure retaining and material replenishing. On the one hand, we should ensure that there is enough molten material, that is, there is material to fill; At the same time, the casting system can not be solidified too early, so that the molten material has a way to go, which is a necessary condition for replenishing material. On the other hand, the injection pressure should be high enough and the pressure holding time should be long enough, which is the sufficient condition for the realization of feeding.

The holding time is usually determined by experiment and cannot be too long or too short. If the pressure holding time is too long, it will not only prolong the molding cycle, but also make the residual pressure in the mold cavity too large, resulting in difficulty in releasing the mold, or even unable to open the mold, in addition, it also increases energy consumption. The best pressure holding time should be to make the residual pressure of the die cavity be zero when the mold is opened. Generally, the molding pressure holding time of nylon 1010 injection parts is 4~50 s.

(3) Demoulding:

Nylon 1010 parts can be demoulded when they are cooled in the mold to have sufficient stiffness. The demoulding temperature should not be too high, which is generally controlled between the thermal deformation temperature of PA1010 and the mold temperature. When demoulding, the residual pressure of the mold cavity should be close to zero, which is determined by the pressure holding time. Generally, the molding time of PA1010 injection parts is: injection time 4~20 s, pressure holding time 4~50 s, cooling time 10~30s.

Source: PA nylon industrial chain

Post time: Mar-09-2023